|

| March 17, 2015 | Volume 11 Issue 11 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Engineer's Toolbox:

NASA's giant crawlers turn 50 years old, pivot toward future exploration

To mark its 50th anniversary, members of the media view the crawler-transporter 2 on Feb. 23 as it travels to Launch Pad 39B at NASA's Kennedy Space Center in Florida. Talking to the media is Mary Hanna, NASA crawler project manager. [Image Credit: NASA]

By Linda Herridge, NASA's John F. Kennedy Space Center

NASA's crawler-transporters, two of the largest vehicles ever built, have carried NASA rockets and spacecraft to the launch pad for the last 50 years. They will continue their legacy as the "workhorses" of the nation's space program as part of the agency's journey to Mars.

The crawlers are being modified to carry NASA's Space Launch System (SLS) with the Orion spacecraft atop it and potential commercial vehicles to their pads to begin space exploration missions. Originally constructed in 1965 to support the agency's Apollo Program, they also supported the Skylab, Apollo-Soyuz Test Project, and Space Shuttle Program, helping NASA push the boundaries of human space exploration farther into the solar system.

To celebrate its 50th year of supporting NASA missions, the upgraded and modified crawler-transporter 2, known as CT-2, rolled out of the Vehicle Assembly Building (VAB) on Feb. 18 and began the 4.2-mile trek to Launch Pad 39B at NASA's Kennedy Space Center in Florida. NASA, members of the media, and guests paid tribute during a viewing and tour of the crawler at the pad Feb. 23.

But there's no time for these giant machines to rest on their laurels. The Ground Systems Development and Operations Program (GSDO) at Kennedy has been busy beefing up crawler-transporter 2 to be ready to support SLS and Orion. CT-1 will be available to carry a variety of other launch vehicles.

Using these vehicles, NASA will send astronauts farther than ever before, first to an asteroid, and onward to Mars. The modifications will enable the crawlers to continue supporting human spaceflight for another 20 years.

The crawlers were initially manufactured by the Marion Shovel Company in Marion, Ohio. Weighing in at more than 6 million lb each, the larger parts that could be assembled and fit on a truck were shipped to Kennedy in 1964, where final assembly took place.

Each crawler is 131 ft long and 114 ft wide, with four pick-up points spaced 90 ft apart on the upper deck that fit into four interface locations on the mobile launcher.

"It's important to maintain an equal amount of weight distributed on each of the crawler's trucks," said John Giles, crawler project deputy manager. "Through tests and calculations, the center of gravity is determined for the mobile launcher. The interface locations can be different according to the weight and location of the space vehicle on top."

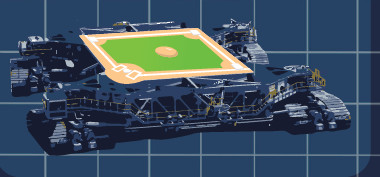

Crawler-transporter 2 continues its trek to Launch Pad 39B at NASA's Kennedy Space Center in Florida on Feb. 20. [Image Credit: NASA/Amber Watson]

The unique features of the giant vehicles include 16 traction motors, two alternating-current generators, two direct-current generators powered by diesel engines, and two control cabs each to drive the vehicles forward and backward. The jacking, equalizing and leveling (JEL) system, among other systems, is monitored and controlled from inside the crawler's control room. The JEL system keeps the upper deck and pick-up points level at all times, even when traveling up steep inclines to the top of the pads, to prevent its rocket payload from toppling.

The crawlers' other unique features are the giant tracks, or treads, that propel the vehicles along. There are eight treads, two per corner, with each tread containing 57 "shoes." Each shoe is 7.5 ft long and 1.5 ft wide and weighs 2,100 lb.

The original shoes were provided by Marion and were replaced in 2004 with new shoes manufactured by ME Global Manufacturing in Duluth, MN. In 1985, a laser docking system was added to the crawlers, allowing them to dock within 0.50 to 0.25 in. of the fixed "dead zero" position at the launch pad and in the VAB.

Traveling at only about 1 mph, the crawlers carried the weight of the massive Saturn V rocket and Apollo capsule attached to the mobile launcher along with the launch umbilical tower (12.3 million lb), and the space shuttle with solid rocket boosters and external fuel tank on top of the mobile launcher platform (11 million lb).

The first use of a crawler was in August 1967, when the first Saturn V rocket for Apollo 4, an uncrewed mission, was transported to Launch Pad 39A.

To date, CT-1 has traveled 1,960 miles, and CT-2 has traveled 2,207 miles to and from the pads.

Crawler-transporter 2 begins its trek to Launch Pad 39B after exiting the Vehicle Assembly Building at NASA's Kennedy Space Center in Florida on Feb. 19. [Image Credit: NASA/Amber Watson]

NASA's GSDO Program has made steady progress on the crawlers' refurbishment since the last space shuttle rolled to the pad in June 2011.

In November 2011, CT-2 moved the SLS mobile launcher from the park site beside the VAB to Launch Pad 39B during a rollout test.

In 2012, CT-2's original alternating-current generators and associated parts were removed. Two new 1,500-kW diesel engines and generators were installed. Work continued over the next two years to modify and upgrade the crawler to extend the life of its operating systems, including the installation of 88 new traction roller bearing assemblies, a modified lubrication delivery system, and a new temperature monitoring system.

In January 2014, CT-2 passed the first phase of an important milestone by completing a test of the new traction roller bearings on two of the massive vehicle's truck sections, A and C, followed by upgrades and testing on truck sections B and D.

The JEL cylinders, electronics, cables, and hydraulic components are being upgraded to increase load-carrying capacity. The upgrades are necessary to increase the lifted-load capacity of the crawlers from 12 million to 18 million lb to support the weight of the SLS and Orion spacecraft on the mobile launcher.

CT-1 is being strengthened to handle commercially operated rockets and spacecraft. "The crawlers are ready to support NASA's SLS program and commercial missions for the next half century," Giles said. "This continued support would not be possible without the managers, engineers, and technicians that maintain these highly unique and specialized pieces of equipment."

NASA crawler fun facts

* A baseball diamond can fit on top of the crawler.

* When placed side by side, three crawlers would take up an entire regulation-size football field.

* After modifications, one crawler-transporter will be able to lift up to 18 million lb. Two modified crawlers would be able to move the St. Louis Gateway Arch. (The Gateway Arch weighs 34,652,000 lb, not including the foundation)

* The new generators installed in the crawlers each produce 1,500 kW -- enough power to run 17 International Space Stations.

* The crawlers are critical elements to enable future launch operations for NASA's Journey to Mars. They could also be major players in Kennedy's transition to a multi-user spaceport with one able to take commercially operated rockets and spacecraft to the launch pad, while the other is being strengthened to handle the Space Launch System (SLS) and Orion spacecraft atop the mobile launcher, a combination heavier than the Saturn V moon rockets the crawlers were designed to carry.

Fun facts courtesy: NASA.gov

Published March 2015

Rate this article

View our terms of use and privacy policy